Our Story

Turbo Air Products

We manufacture commercial refrigerators and freezers, supermarket equipment, cooking equipment, and walk-in system units.

Turbo Air has all your food service equipment needs with over 500+ refrigeration units.

Global Sales

Manufacture facilities are located in Texas, South Korea, and China.

Turbo Air sells products in 67 countries.

Fast Warranty Service & Parts Supply

There are 13 Turbo Air warehouses and 15 parts distribution centers nationwide that provide same day to 3 day shipping.

Service Provider Network

Our friendly customer service agents and tech support team is ready to help any customer. Our company employed technicians are experienced and professionally trained on Turbo Air products to provide exceptional services.

Excellent Quality Control

Our R&D and Quality Control Department strive to improve performance, energy efficiency, and meet the customers’ needs through technological enhancement.

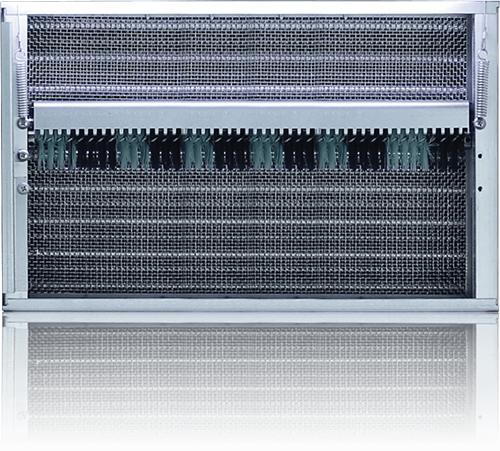

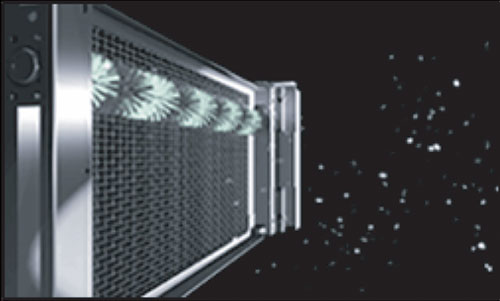

Self-Cleaning Condenser

Our patented Self-Cleaning Condenser is an innovative feature that uses a fine mesh filter to catch the dust. While the rotating brush moves up and down to remove the excess outward and away from the condenser – effectively preventing dust from accumulating in the first place.

Turbo Air Products have..

Outstanding

Reliability

Superior

Functionality

Excellent

Convenience

Turbo Air Technology

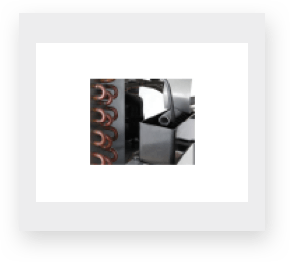

Self-Cleaning Condenser

How does it work?

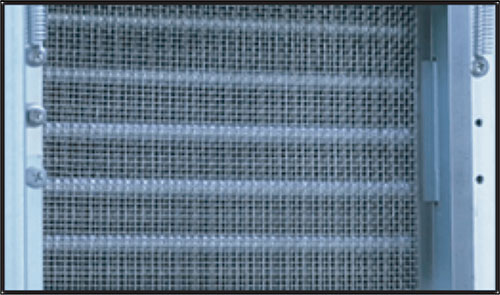

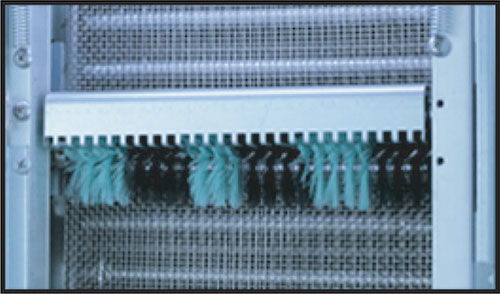

Turbo Air’s patented Self-cleaning Condenser is an innovative feature that uses a fine mesh filter to catch the dust, while the rotating brush moves up and down 2~3 times a day to remove the excess outward and away from the condenser, effectively preventing dust from accumulating in the first place. This allows your system to maintain the highest efficiency while mitigating premature system failure.

Fine Mesh Filter

Rotating Brush

Preventing Dust Build Up

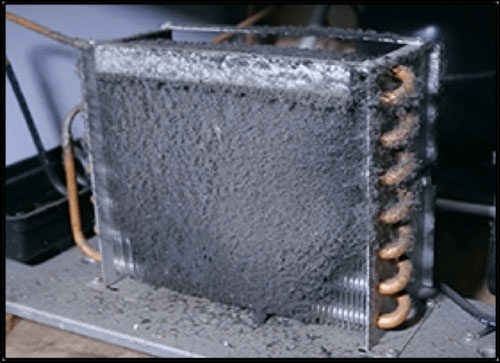

Dirty Condenser

What does a dirty condenser cause?

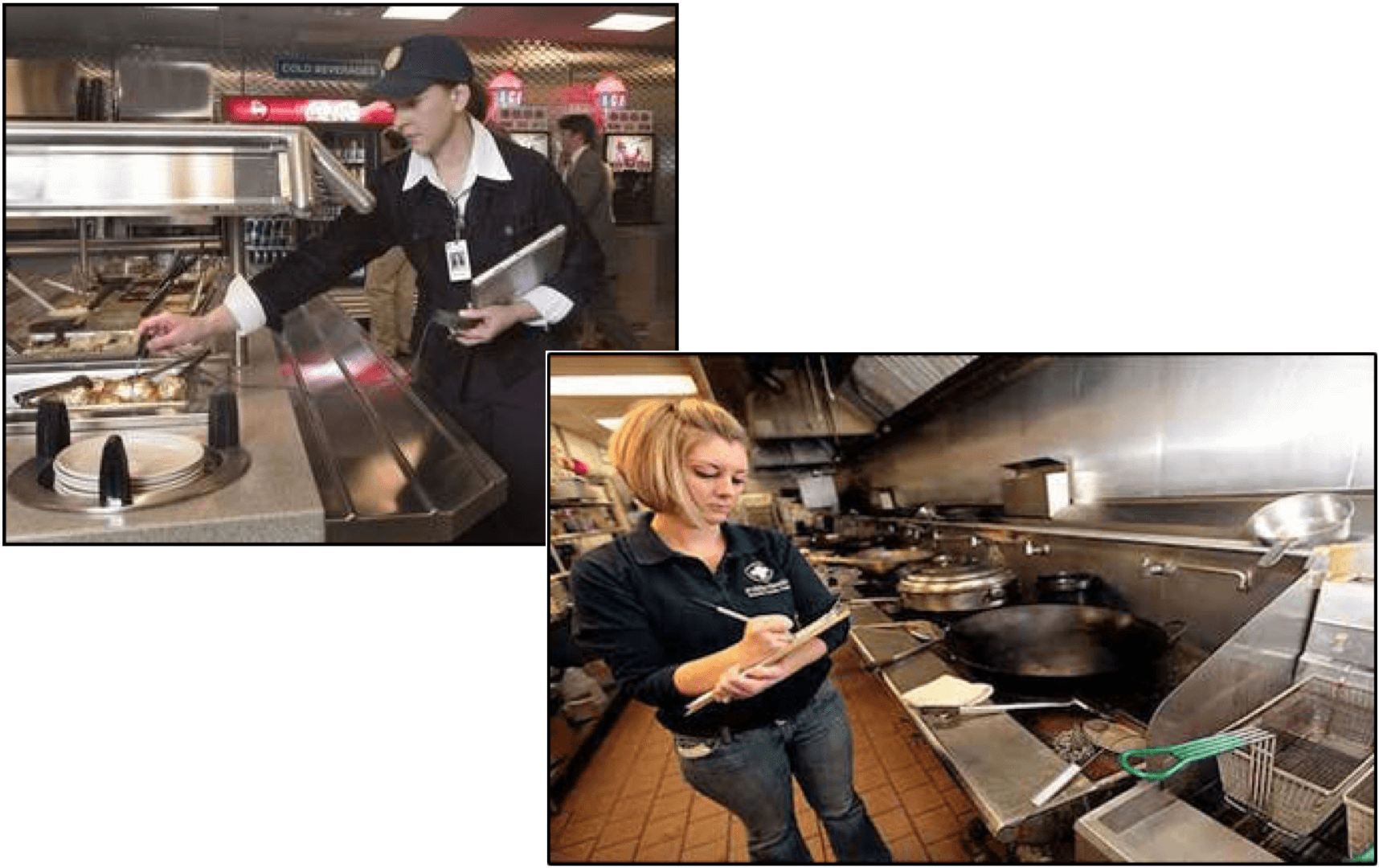

Dirty Condensers

Busy marketplaces and restaurant kitchen spaces with heavy traffic accumulate massive amounts of dust quickly, leading to dirty condenser. Dirty condenser can cause major issues when neglected without proper maintenance such as; increased energy consumption, compressor failure, health inspection failure and manufacturer warranty void.

Dirty condenser coils are one of the most frequent service problems in commercial refrigeration.

Innovation for Solutions

Patented Standard Feature

Turbo Air’s Self-cleaning Condenser is a standard feature. Our customers can benefit from this excellent option on most of our product lines without spending any extra money.

Turbo Air’s top priority is our customers. We understand your business. Turbo Air will continue to strive to provide better solutions to this industry and, most importantly, to our customers.

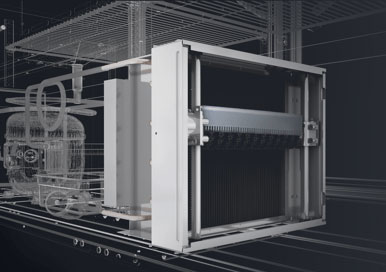

Self-Cleaning Condenser System

Marketplaces that experience heavy traffic produce plenty of dust. Dust is then drawn through the fan and accumulated, preventing the condenser from properly releasing heat. This in turn causes the compressor to increase its pressure on refrigerants, adding to the possibility of the compressor from breaking down. The ‘Self-Cleaning Condenser System’ cleans the condenser with a rotating brush that moves up and down 2-3 times a day, preventing any dust build-up and makes it possible to constantly maintain the highest efficiency while saving additional energy.

Energy Saving Fan Controller

Located inside the refrigerator is a fan motor that runs 24 hours non-stop to circulate cold air throughout the unit, and this mechanism can generate significant amounts of heat. When the compressor is not running, this heat can cause a reversal effect in increasing the interior temperature instead of cooling it. To solve this issue, Turbo Air engineers have tirelessly researched and experimented to come up with the perfect algorithm that stops the fan motor from running as soon as an increase in temperature is detected. This ultimately translates to 15%-25% in overall energy savings as well as an increase in the overall lifespan of the compressor.

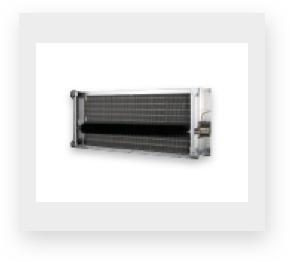

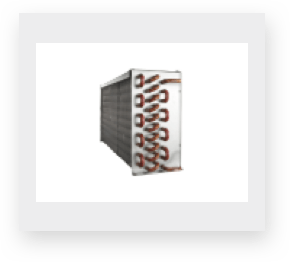

Larger Condensers

Refrigerators receive its cooling effect by discharging heat through the condenser. To achieve high efficiency in an environment (such as the kitchen) where temperatures are ambient and humidity is relatively high, it is important to increase the effectiveness of condensers. Turbo Air uses condensers that are 10 ~ 20% larger than the industry standard.

No Electrical Cabenet Heater Is Needed

Electrical heaters in freezers operate 24/7 in order to prevent water flow to the cabinet surface. This causes unnecessary energy consumption, and sometimes is the reason behind overheating. Instead of frame heaters, Turbo Air freezers harness the heat produced by the compressor during its condensing stage, eliminating any unnecessary energy consumption as well as providing the most efficient freezer performance available.

Condensate Water Cooling System

Unique to Turbo Air products, our anti-corrosion pipes are coated on the surface with a special treatment, allowing the excess condensate waters to cool down the pipe’s hottest area during the refrigerant compression process. This not only saves energy, but also allows the elimination of additional drains, which prevents the possibility of slippery floors becoming a safety issue.

Turbo Cooling & Freeze Feature For Faster Chilling

The Turbo Cooling and Freeze function, located on the control panel, allows the compressor to run continuously for up to two hours. When this function is activated, the temperature inside the cabinet quickly decreases and cools drinks, food, and other products much faster. An ideal time to use the Turbo Cooling and Freeze function is when the unit is stocked with new products.

60MM Thick High Density Wall

To prevent heat transfer from where it’s produced the most (compressor room), Turbo Air designed a specially reinforced 60mm thick, high-density wall to create a greater insulation effect and to also increase the overall efficiency.

Prenventing Heat Transfer

Unique to Turbo Air products, our anti-corrosion pipes are coated on the surface with a special treatment, allowing the excess condensate waters to cool down the pipe’s hottest area during the refrigerant compression process. This not only saves energy, but also allows the elimination of additional drains, which prevents the possibility of slippery floors becoming a safety issue.

LED Lighting Interior Display System

Fluorescent lights emit enormous amount of heat and consumes more energy—Turbo Air products use LED lights to reduce energy consumption and to create greater lifespan. It also uses optimal light angles for enhancing its display effects.

Shadow Free High Resolution AD Panel

We used the most cutting-edge LED TV technology for our advertising panels. Every inch of our panel illuminates at the same brightness, producing a luxurious ambience while increasing its advertising effect. Our AD panels are also 5 times longer lasting and energy efficient than fluorescent light powered panels.

Energy Star Partner

Turbo Air has 120+ Energy Star certified models and counting.

We built our products to rely on their naturally emitted energy, thus reducing electrical energy consumption. Turbo Air strives for sustainability without sacrificing performance and durability.

![]()

Natural Refrigerant

Natural refrigerant is used in all Turbo Air refrigeratorsThe most common refrigerants that have been used in the industry are HFCs (hydrofluorocarbons R-134a, R-404A), replacements for CFCs (chlorofluorocarbons) which are harmful substances proven to deplete the ozone layer. HFC’s are not directly ozone-depleting but these strong greenhouse gases have been shown to have a negative impact on the environment, contributing to global warming up to 4,000 times more than CO2. These GWP refrigerants are listed among substances regulated by the Kyoto Protocol of 1992, and HFC substances such as R-134a and R-404A will be banned by new U.S government regulations starting January 1, 2019.

The industry must embrace the new climate-friendly natural refrigerant HC (hydrocarbons).

What is Hydrocarbon?

HC (hydrocarbon) is a sustainable alternative to HFC. Hydrocarbons (R-600A, R-290) are natural refrigerants that have no ODP (ozone depleting potential) and very low GWP (global warming potential). Moreover, HC based equipment have been shown to be more energy efficient compared to HFC based equipment, which translates to lower operating costs. The EPA approved R-290 (Propane) and R-600A (Isobutane) as acceptable refrigerants for use in commercial refrigeration, stand-alone equipment refrigerators, and freezers.